For Prelims: Steam Digester, Denis Papin’s Steam Digester, Steam Digester by Denis Papin, Denis Papin

For Mains: Denis Papin’s Steam Digester, Steam Digester by Denis Papin

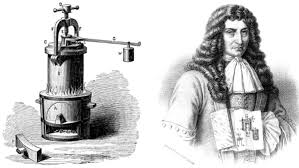

The history of industrial science is rich with overlooked innovations that quietly laid the groundwork for revolutionary advancements. One such invention is Denis Papin’s _Steam Digester_, developed in 1679. While often overshadowed by the later development of the steam engine, Papin's device was a remarkable leap in harnessing the power of steam. For students, engineers, and industrial historians alike, the _Steam Digester_ offers a crucial glimpse into the origins of modern thermodynamic technology.

[JPSC Boiler Inspector Exam 2025: Notification, Eligibility, Syllabus, Age Limit and Complete Details](https://learnpro.in/jpsc-boiler-inspector-exam-2025/)

*

1\. The Intellectual Climate of the 17th Century

The 1600s marked a transitional period in European science. With the Renaissance fading and the Scientific Revolution in full swing, the intellectual curiosity of figures like Galileo, Boyle, and Newton was reshaping the understanding of nature and physics. Yet, when it came to mechanical energy and steam, progress had stagnated since Hero of Alexandria's Aeolipile, a device that demonstrated rotational motion using steam as early as the 1st century CE.

It wasn't until Denis Papin, a French physicist, mathematician, and inventor, entered the scene that a functional and controlled application of steam became possible.

*

2\. Who Was Denis Papin?

Denis Papin (1647–1713) was a polymath and a student of Christiaan Huygens and Gottfried Leibniz. With a background in both experimental physics and engineering, Papin was uniquely positioned to blend scientific theory with mechanical practicality. His work bridged the gap between theoretical physics and industrial application, making him a pivotal but often underappreciated figure in engineering history.

His most iconic creation, the Steam Digester, arose from his exploration of how heat and pressure could be manipulated to improve efficiency—in this case, initially in cooking meat and bones.

*

3\. The Steam Digester: Design and Operation

At first glance, the Steam Digester may appear deceptively simple. However, its internal dynamics introduced a novel concept: controlled high-pressure steam.

#### Structure and Composition

- The digester was essentially a sealed metal vessel capable of withstanding high internal pressures.

- It had a tightly fitted lid secured with clamps or screws to ensure it remained closed during operation.

- Inside the vessel, water and organic material (e.g., meat, bones) were placed.

#### How It Worked

- As the vessel was heated externally, the water inside boiled.

- In a sealed container, boiling point increases with pressure. Instead of vapor escaping, the steam accumulated.

- This caused the internal pressure and temperature to rise, resulting in much faster cooking times and greater extraction of nutrients.

In essence, it functioned like a pressure cooker, but its implications extended far beyond the kitchen.

[](https://learnpro.live/new-courses/48-jpsc-boiler-inspector)

*

4\. The Key Breakthrough: Safety Valve Mechanism

One of Papin’s most critical contributions was the inclusion of a safety valve, a feature so revolutionary that it persists today in nearly all pressure-based systems, from boilers to nuclear reactors.

#### Design of the Safety Valve

- Papin devised a weighted lever mechanism or a spring-loaded valve attached to the lid.

- When the internal pressure surpassed a safe threshold, the valve would automatically lift, allowing excess steam to escape.

#### Why It Mattered

- Before this innovation, the idea of sealing a vessel under pressure was inherently dangerous. Explosions were common.

- Papin's valve introduced a method to regulate internal pressure, ensuring that the device could operate safely.

- This simple yet profound addition laid the groundwork for safe high-pressure engineering.

*

5\. Scientific and Industrial Significance

The Steam Digester was not merely a cooking device. It was a proof of concept—a working model demonstrating that steam could be harnessed, controlled, and made to do useful work safely.

#### From Curiosity to Capability

- Steam had long been regarded as a natural phenomenon, often observed in volcanoes or geysers.

- With the digester, Papin transitioned steam from a curiosity to a controllable force, something that could be measured, manipulated, and applied.

#### Foundational for Steam Engines

- Papin's invention predated the steam engines of Thomas Savery (1698) and Thomas Newcomen (1712).

- It directly influenced their work by proving that mechanical energy could be derived from steam pressure.

- Without Papin’s design and safety valve, early steam engines may have remained too dangerous for practical use.

*

6\. Impacts on Engineering Education and Thermodynamics

For students of mechanical engineering, fluid dynamics, and thermodynamics, the Steam Digester remains a compelling educational tool.

#### Core Concepts Introduced

- Pressure-Temperature Relationship: Papin's device helped demonstrate how pressure raises boiling point.

- Closed System Dynamics: A precursor to modern Rankine cycles used in power plants.

- Safety Engineering: Early lessons in managing risk with mechanical systems.

#### Curricular Value

- The Steam Digester is now often used in engineering history courses to teach the evolution of industrial design.

- It offers a tangible link between abstract physics principles and real-world applications.

*

7\. Legacy and Influence

Despite its limited commercial use, the Steam Digester’s legacy is immense.

#### Influence on Future Technologies

- Steam Boilers: Papin’s vessel was essentially a prototype of the modern steam boiler.

- Automated Safety Systems: The safety valve inspired future pressure-release designs in engines and industrial kettles.

- Power Engineering: His principles underlie turbine design, steam locomotives, and thermal power stations.

#### Tributes and Recognition

- Though not widely remembered, Papin’s contributions have been acknowledged by scientific bodies in both France and the UK.

- His name is often invoked in discussions of pre-industrial revolution engineering breakthroughs.

*

8\. Modern Reflections: Relevance in Today’s World

Even in an age dominated by nuclear and renewable energy, the foundational principles demonstrated by Papin continue to matter.

#### Continued Use of Steam Systems

- Steam turbines still power over 80% of the world’s electricity.

- Industrial autoclaves and pressure vessels in medical, aerospace, and food processing industries rely on similar pressure control mechanisms.

#### Lessons for Today’s Engineers

- Innovation often starts in unexpected domains (e.g., a cooking vessel leading to industrial power).

- The intersection of science, safety, and design is critical for technology to move from laboratory to factory.

*

Conclusion

The invention of the Steam Digester by Denis Papin marked one of the earliest—and most critical—steps toward industrial modernity. By converting theoretical steam principles into a working mechanical system with built-in safety, Papin laid the intellectual and technical foundation for the development of steam engines and pressure-based technology.

For students seeking to understand the origins of mechanical innovation or professionals exploring the roots of industrial engineering, the Steam Digester is far more than a historical footnote. It is a case study in foresight, experimentation, and transformative thinking.